Scientists have long grappled with the persistent environmental crisis posed by polyethylene terephthalate (PET), one of the most widely used plastics in packaging and textiles. With millions of tons ending up in landfills and oceans each year, the search for sustainable solutions has intensified. A groundbreaking discovery in marine microbiology may hold the key: a specialized enzyme produced by ocean-dwelling bacteria capable of breaking down PET into harmless components. This natural "enzyme scissors" mechanism could revolutionize plastic waste management and pave the way for industrial-scale biodegradation.

The discovery centers around Ideonella sakaiensis, a bacterium first identified in 2016 at a PET-contaminated waste site in Japan. Researchers observed that this microorganism secreted two unique enzymes—PETase and MHETase—which work in tandem to dismantle PET polymers at the molecular level. While initial lab results were promising, the enzymes' natural degradation process was too slow for practical applications. Recent genetic engineering breakthroughs, however, have enhanced their efficiency by 20-fold, making industrial deployment a tangible possibility.

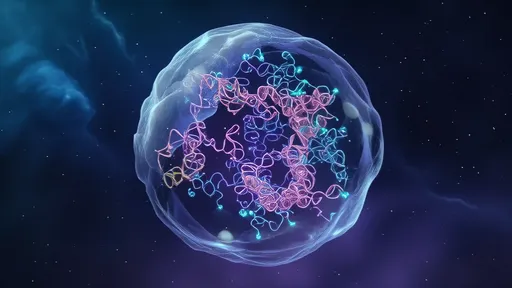

What sets this approach apart is its biomimetic elegance. Unlike energy-intensive mechanical recycling or toxic chemical processes, enzymatic degradation operates under mild temperatures and leaves no hazardous byproducts. When the enhanced enzymes encounter PET, they cleave the ester bonds holding the polymer chains together, reducing the plastic to its basic building blocks—terephthalic acid and ethylene glycol. These monomers can then be purified and repolymerized into virgin-quality PET, creating a true circular economy loop.

The marine origin of these plastic-eating bacteria offers another critical advantage. Having evolved in ocean environments where PET debris accumulates, their enzymes function effectively even in saline conditions—a stark contrast to land-derived fungal enzymes previously studied. This salt tolerance proves invaluable for treating plastic waste harvested directly from marine ecosystems without costly desalination steps. Pilot projects in coastal cleanup initiatives have demonstrated 85% PET depolymerization within 72 hours using seawater-based reaction systems.

Scaling this technology presents both opportunities and challenges. Biotechnology firms in Europe and Asia are racing to develop immobilized enzyme reactors where plastic waste flows through cascading chambers housing the engineered enzymes. Early prototypes process 5 metric tons of PET weekly, but economists note production costs must drop below €300 per ton to compete with conventional recycling. Strategic partnerships with beverage companies—major PET consumers—are helping bridge this gap through co-funded research and waste feedstock agreements.

Environmental chemists caution that enzymatic recycling isn't a panacea. The process currently struggles with colored or multilayered PET packaging containing additives. Some researchers propose hybrid systems combining mild chemical pretreatment with enzymatic finishing steps. Meanwhile, synthetic biologists are creating "designer enzyme cocktails" by fusing PETase with other hydrolytic enzymes to broaden the spectrum of digestible plastics.

As patent filings surge and pilot plants multiply from Rotterdam to Osaka, the vision of industrial-scale enzymatic PET recycling inches closer to reality. With ocean plastic pollution reaching crisis levels, this marine microbial solution exemplifies nature's ingenuity in addressing human-made problems. The coming decade will determine whether these microscopic "enzyme scissors" can cut through both plastic waste and economic barriers to deliver an environmental transformation.

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025